Indicators on Plastic Bottle Suppliers You Need To Know

Table of ContentsPlastic Bottle Suppliers for BeginnersPlastic Bottle Suppliers for BeginnersWhat Does Plastic Bottle Suppliers Do?Plastic Bottle Suppliers Things To Know Before You Get ThisUnknown Facts About Plastic Bottle Suppliers

Once the polymer material has cooled enough to solidify, the mould is opened up and also the bottle caps are expelled. If numerous caps are being made from a solitary mould (as is typically the situation), they will certainly be meticulously separated from each other and get ready for additional processing (e - plastic bottle suppliers. g., wadding, sealing).Injection moulding is the most usual production approach for container caps for numerous very great reasons. For example, injection moulding is extremely cost reliable for huge manufacturing runs. It likewise exhibits high repeatability, which implies there will be virtually no variant in measurement, shape, or surface finish from cap to cap and even set to set.

The moulds used support high levels of information and make it easy for premium quality embossing to be included (which will certainly be discussed further on in a separate section). Shot mould utilized for making multiple container caps. The moulds themselves are frequently meticulously machined from long lasting stainless-steel and used countless times in a solitary production run.

7 Easy Facts About Plastic Bottle Suppliers Explained

When it comes to container caps, the moulds themselves contain the inverse form of the container cap, consisting of the strings and also whatever will certainly be embossed on the top and/or sides of the cap. It is very important that these layout details stay dimensionally secure as the component cools down in the mould, as well as the mould needs to be created to ensure that the part cools uniformly within the mould to prevent distortion of the final shape.

Moulds are costly for container caps due to the intricacy associated with accomplishing the interior thread, which are thought about undercut parts and entail unique mould style factors to consider as well as tooling to ensure that the parts can be removed after cooling down without damages. Nevertheless, when a producing company has already invested in premium quality, complicated moulds for standard bottle cap dimensions and also threading, particular minimum quantities can be manufactured.

In truth, this alternative can really get rid of the requirement for a tag and also can consist of cross advertising or product cautions. Very detailed printed plastic bottle caps that consist of a business logo as well as message. Embossing likewise acts as a fantastic method to draw in the interest of clients or users that could have a tendency to neglect a tag but can not ignore the cover while they are opening the container, especially when embossing is integrated with personalized colours.

Since of just how simple it is to consist of embossing in the bottle cap manufacturing procedure, there is generally no extra price. The lining material between the bottle cap and also the contains of the container is called an as well as can offer various purposes. It can work as a seal to secure the honesty of the contents, safeguarding them from wetness or oxygen.

The Single Strategy To Use For Plastic Bottle Suppliers

Or a wad can make it apparent if somebody has actually tampered with the materials as well as in the instance of a product such as medicine, evidence of meddling might protect against somebody read this article from ingesting something that can make them ill or probably poisonous substance them. Beyond selecting a wad based upon the purpose it have to offer, it is likewise crucial to bear in mind that the heap product encountering the container must be chemically suitable with the materials of the container.

, or, are polycell heaps that have a layer of aluminum foil included in secure the polywad from any kind of chemicals in the container and also support chemical compatibility. include a layer of aluminum foil with wax-like material with an incredibly low melting point on the side towards the container and also its components.

Prior to the process starts, the bottle cap is attached to the container at a certain torque. Next, the container and also cap are passed underneath an oscillating magnetic field. When that magnetic field travels via the air and runs into the metal surface area of the foil, a high oscillating electric current is generated in the aluminum foil.

Indicators on Plastic Bottle Suppliers You Should Know

The entire sealing process is accomplished without the requirement for anything to touch either the bottle or the cap besides relocating them beneath the magnetic field. Only the steel aluminum foil is warmed, as well as after that just sufficient to melt the wax-like substance, so the materials within the container (as well as the container/cap itself) remain completely unmodified as well as unaffected during the procedure. plastic bottle suppliers.

This produces a powerful obstacle to both wetness and oxygen that functions well for products in powder or liquid kind. There is an impressive quantity of detail simply in the style of a bottle cap, with the threading, dimensions, and also option of wadding as well as embossing. As soon as the recyclable plastic and also custom colour has actually been selected, it is shot moulded under incredibly high stress to create a high quality container cap from a complex mould.

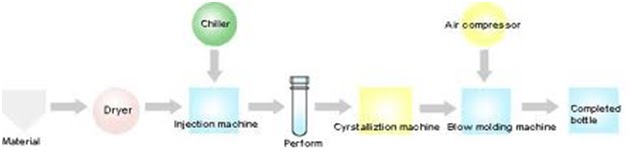

TASK REPORT Address The international plastics market is observing a continual shift of manufacturing bases to affordable Asian nations. With increasing international investment and also rise in the variety of new production facilities in the region, Asia has actually come to be the largest and also the fastest growing market for plastics on the planet. The mold and mildew contains a core side as well as a cavity side that is put into a plastic shot molding device. This equipment heats up the raw plastic material pellets until they're thawed, injects them right into the empty dental caries of the mold under excellent pressure, and also after that available to expel the finished part.

Molds nonetheless can be expensive and complicated, depending on the part geometry. Cautious engineering style of the mold and mildew is required to stop issues and optimize part high quality and also handling speed. Rotational molding likewise utilizes a core and also dental caries mold tool, however the production process is rather various. Plastic powder is put into the cavity of the mold, as well as the mold and mildew placed in an oven.

Plastic Bottle Suppliers - Truths

Gravity is home utilized to stick the plastic to the tool walls as well as accumulate the correct thickness. After that, the mold is removed from the oven as well as gradually cooled to avoid warpage. plastic bottle suppliers. Complete air conditioning can take several minutes, he said after which the device is opened up as well as the part got rid of for the following cycle.

The finished components are worry-free and also have no seams so they're solid, as well as the tools are reasonably basic as well as low-cost to make. The drawback is that tools do not last greater than a few thousand cycles prior to they need to be replaced, and also the component end up high quality is average at best so it's not suited for accuracy developing.